New dimensions in load capacity, reach and tensile load!

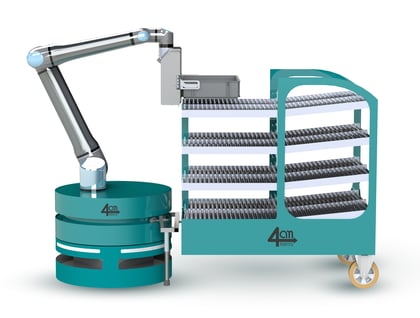

Automate even complex material flow tasks. Take your intralogistics to a new level with the AMC-H.

High manipulation weight

Easily picks goods weighing up to 15 kg (33.1 lbs)

The strength of the AMC-H in combination with its other advantages in terms of reach and tractive force make it a real game changer in small load carrier handling.

Strong range

Impresses with a range of almost 2 metres

Its UR20 gripper arm allows goods to be picked both upwards and downwards with the same reach range. Precise load handling is complemented by an extensive range of grippers.

High tractive force

Transports loads of up to 500 kg in the optional trailer (1,102.3 lbs)

This powerhouse utilises the SLAM process for autonomous and situation-specific navigation. In conjunction with safety laser scanners and 3D cameras, it navigates safely even in complex environments.

New standards in autonomous intralogistics with the AMC-H

With its performance features, this innovative mobile cobot sets new standards in terms of payload, reach and tensile load. The new AMC-H masters complex tasks that were previously reserved for human operators, setting new standards in the autonomous use of mobile cobots. Designed specifically for handling small load carriers, we have created a space-saving platform that uses the SLAM process to move autonomously in any direction and handle loads with unrivalled precision. In conjunction with safety laser scanners and 3D cameras, the AMC-H is able to navigate autonomously even in complex environments. It constantly updates the map of its surroundings and simultaneously localises itself within it in order to carry out precise movements. This allows the AMC-H to be used flexibly and efficiently in different environments - without additional markers or adjustments.

The strength of the AMC-H lies in the variability of the gripping system, which can be customised to the specific requirements of your production process. Integration into any master control system for order coordination not only optimises the material flow, but also enables flexible and needs-based adaptation to different processes. The high round-the-clock availability of the AMC-H, supported by fast charging cycles and the ability to operate in low-light environments, offers an efficient alternative in times of a shortage of skilled labour.

Trailer module for more throughput

To enable more material to be transported over longer distances, the AMC can be extended with an innovative trailer system with a towing capacity of up to 500kg (1,102.3 lbs).

The pivot point of the trailer coupling is aligned with the centre of the base. This means that the AMC can turn on the spot while the trailer simply remains stationary.

This ensures smooth and space-saving manoeuvring along the route.

Technical data AMC-H

-

Manipulation Weight: max. 15 kg (33.1 lbs)

-

Tractive force: 500 kg (1,102.3 lbs)

-

Range: ca. 2.000 mm (ca. 78.7 in)

-

Vmax 2,2 m/s (4.9 mph)

-

Boxes: KLT/Eurobox max. 600x400 mm (23.6x15.7 in) (WxL) / max. 320 mm (12.6 in) height

-

Positioning precision: +/- 10 mm (+/- 0.39 in)

-

WiFi, 4G/5G, VDA5050

You want more information on our products?

Please register with us, easily, via eMail address and you will get immediate access to our download area.

There you will find all product information at any time.

Intelligent navigation. Proven safety.

SLAM technology for autonomous navigation

By using the SLAM process (Simultaneous Localisation and Mapping) in conjunction with safety laser scanners and 3D cameras, the AMC-H navigates safely even in complex environments. It constantly updates the map of its surroundings and simultaneously localises itself in order to carry out precise movements. And it does this without additional markers and without prior adjustments.

High availability and use in low-light environments

The 24/7 availability of the AMC-H, supported by fast charging cycles and the ability to operate in low-light environments, offers a powerful alternative in times of a shortage of skilled labour.

Proven safety

We attach great importance to safety and subject our products to all standard safety tests. The AMC-H fulfils performance level d, which means that it guarantees a high level of safety and therefore reliability during navigation and operation. This is particularly important in order to minimise potentially hazardous situations and ensure a smooth and reliable workflow.

As flexible as you are: gripping systems perfectly tailored to your production process.

The AMC-H is equipped with an adaptive box gripper system that is specially optimised for handling small load carriers. This gripper system offers unrivalled flexibility to handle a wide range of object sizes and shapes. The patented box gripper enables highly efficient handling of small load carriers and is characterised by its precision and versatility.

In addition, an extensive range of gripping options is available that are optimised for a wide variety of process requirements. In addition to the box gripper developed and patented by 4am, these also include vacuum grippers and 2-finger grippers.